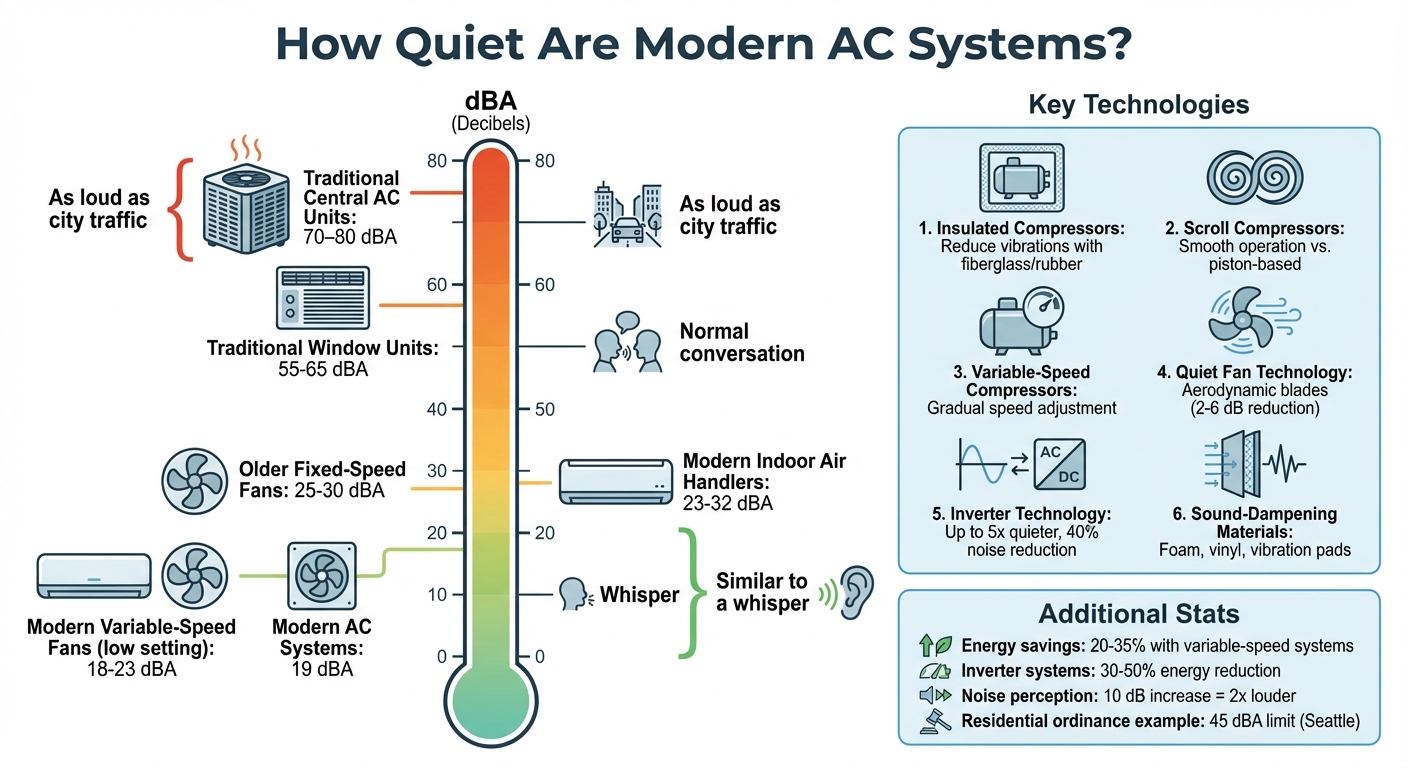

If loud air conditioners have ever disrupted your sleep or focus, you’re not alone. Modern AC systems now offer noise-reducing features that make them quieter than older models. While older central AC units typically operate at 70–80 dBA (as loud as city traffic), newer models can run as quietly as 19 dBA – similar to a whisper. Here’s how they achieve this:

- Insulated Compressors: Reduce vibrations and trap noise with materials like fiberglass or rubber.

- Scroll Compressors: Operate more smoothly and quietly than traditional piston-based designs.

- Variable-Speed Compressors: Avoid loud on/off cycles by adjusting speed gradually.

- Quiet Fan Technology: Aerodynamic blades and variable-speed motors lower fan noise.

- Inverter Technology: Maintains consistent cooling with soft-start compressors, eliminating harsh start/stop sounds.

- Sound-Dampening Materials: Foam, vinyl, and vibration pads absorb and block noise from escaping.

These advancements not only improve comfort but also help lower stress and enhance productivity at home. Proper installation is key to maximizing these benefits, ensuring quieter operation and better performance.

Noise Levels Comparison: Modern vs Traditional AC Systems

Insulated Compressors

The compressor is often the loudest part of your AC system – it’s essentially the heart of the operation. Insulated compressors tackle this noise problem head-on by using materials that absorb sound and reduce vibrations. These advancements have significantly improved how quietly modern systems run, setting the stage for even more noise-reducing breakthroughs.

Acoustic Insulation

To keep compressor noise in check, manufacturers rely on a variety of sound-dampening materials. For instance, quilted fiberglass and mass-loaded vinyl act as sound barriers, forming customized blankets that trap noise before it escapes. Inside the AC cabinet, acoustic foam or polypropylene panels are commonly installed to further absorb sound. Some systems even use viscoelastic compounds like Green Glue, which convert vibration energy into heat, cutting down on noise transmission. Additionally, refrigerant lines are insulated with foam or rubber sleeves where they touch walls, reducing any buzzing caused by friction.

Scroll Compressor Design

Scroll compressors take noise reduction a step further by rethinking how the system operates. Unlike traditional piston-based compressors, which use pins and rods that can create loud banging as they wear down, scroll compressors rely on a smooth, continuous orbital motion. This design eliminates the high-impact parts that often cause noise. HVAC expert Mark Callahan highlights this difference:

High-quality quiet AC compressors reduce vibrations and operate more smoothly.

To make things even quieter, manufacturers use rubber mounts or isolation pads to prevent cabinet rattling. Together, these features make scroll compressors significantly quieter than older models.

Variable-Speed Operation

Another key improvement is the introduction of variable-speed compressors, which avoid the loud on/off cycles of traditional systems. Instead of abruptly toggling between full power and off, these compressors gradually adjust their motor speed to match the cooling needs of the room. Chris Regan, Head of Air Conditioner Testing at Consumer Reports, explains:

An inverter air conditioner adjusts the speed of the compressor, and as the room gets cooler, it ramps down the speed.

This gradual adjustment leads to a consistent, quiet hum rather than the jarring roar of a motor starting or stopping. It’s a game-changer for maintaining a peaceful environment.

Quiet Fan Technology

Fans play a big role in reducing noise in modern AC systems. Today’s designs borrow from aerodynamics and aviation, using blade shapes that cut through air with less turbulence. For instance, outdoor fans now feature aerofoil-shaped blades – similar to airplane wings – that reduce resistance and noise. Many also include winglet-style tips to suppress vortex-induced noise, shaving off 2–6 dB of sound compared to older designs.

Inside the unit, blower wheels are crafted with precision geometry to minimize the high-pitched sounds of fast-moving air. Instead of belt-driven fans, which can squeal when belts slip, systems now use direct-drive motors for quieter operation. HVAC expert Jake Lawson puts it simply:

Comfort isn’t just temperature. It’s how silently your AC delivers it.

Here’s a closer look at the features that make these fans so quiet.

Optimized Blade Shapes

Fan blade design has a huge impact on airflow and noise. Anti-vortex blade geometries are specifically engineered to reduce turbulence as air exits the blade. Think about the difference between a gentle breeze and a gusty wind – when air leaves a blade chaotically, it creates noise. These specialized shapes smooth out airflow, keeping the system quieter. Regularly cleaning the blades is also key to preventing imbalance and extra noise.

Variable-Speed Fans

Variable-speed fans, powered by Electronically Commutated Motors (ECM), adjust their speed based on cooling demands in real time. Unlike older PSC motors that jump straight to full speed, ECM motors ramp up gradually, avoiding the loud startup noise. These fans often run at lower speeds for longer periods, which not only keeps the temperature steady but also reduces noise from constant cycling. In tests, systems with variable-speed fans recorded indoor noise levels of 18–23 dB on low settings, compared to 25–30 dB for older models.

Quiet Mode Settings

Many modern AC systems now include "Sleep" or "Quiet" modes, designed to tone down noise at night. These settings lower fan RPM, creating a softer sound and reducing the hiss from air registers. Instead of sudden temperature changes that cause noisy fan speed shifts, quiet modes make gradual adjustments, keeping the room comfortable without disturbing sleep. Ductless indoor units in quiet mode can achieve sound levels in the high teens to low 20s dB range. HVAC expert Michael Haines highlights the importance of proper unit sizing:

A unit that measures quietly only on its lowest setting but must run on medium to hold setpoint will not feel quiet at 2 a.m.

To maximize quiet operation, enable Sleep Mode and ensure at least 24–36 inches of clearance around outdoor units to reduce sound reflections.

Inverter Technology

Traditional air conditioning systems function like a basic light switch – they’re either fully on or completely off. Inverter technology, on the other hand, works more like a dimmer switch, constantly adjusting the compressor’s motor speed to match your home’s cooling needs precisely. This approach introduces a smoother and quieter operation, thanks to soft-start technology, which gradually ramps up the compressor’s speed. This eliminates the abrupt "start-up clunk" and "shutdown thump" commonly associated with older systems. Instead of shutting off entirely when your home reaches the desired temperature, the inverter slows down, maintaining comfort while operating at lower, quieter decibel levels.

The difference in noise levels is striking. Inverter compressors can be up to 5 times quieter than traditional systems. For example, some modern units, like those from Daikin, operate at just 19 dBA – similar to a whisper. By comparison, indoor air handlers typically range between 23–32 decibels, while older window units often reach a much louder 55–65 dBA. As The Furnace Outlet explains:

An inverter compressor acts like a dimmer switch. It constantly adjusts its speed to maintain the exact temperature you set. This eliminates the harsh start-up clunk and shutdown thump you hear in non-inverter units.

Elimination of Abrupt Starts and Stops

Beyond the benefits of soft-start technology, inverter systems further reduce disruptive sound events by operating continuously at variable speeds. This smooth adjustment prevents the sudden "whoosh" of air blasting through vents, a common issue when fixed-speed compressors kick on at full power.

This steady operation cuts noise levels by up to 40% compared to conventional compressors. Instead of intermittent bursts of sound, the system produces a consistent, low-level hum that blends into the background. For spaces like bedrooms or quiet areas, this shift to a steady sound profile makes a noticeable difference. However, to fully benefit from this technology, it’s essential to choose an AC unit appropriately sized for your space. An undersized inverter system will run at maximum capacity constantly, negating its noise-reduction advantages.

Integration with Modern Refrigerants

Inverter technology works hand-in-hand with modern refrigerants to enhance performance and reduce noise. Refrigerants like R-32 offer superior heat transfer capabilities, allowing compressors to cool more efficiently while maintaining lower, quieter speeds. These refrigerants also support soft-start technology, reducing mechanical strain and noise during operation.

R-32 stands out for its efficiency, delivering better cooling while producing fewer emissions. This allows inverters to operate at reduced power levels, which translates to quieter operation without sacrificing temperature control. As TCL notes:

Modern inverter ACs use efficient refrigerants such as R32 which provides better cooling capacity and also emits less harmful emissions to the environment.

Additionally, these refrigerants enable variable-speed fans to maintain temperatures with less airflow, further minimizing the "hiss" from registers and motor noise. Together, inverter technology and advanced refrigerants can lower energy consumption by 30% to 50% compared to older systems. Some advanced inverter units even operate as quietly as 45 dB(A) in quiet mode.

sbb-itb-b5c10b1

Sound-Dampening Materials

Even with modern compressor and fan technology, some noise is unavoidable. Sound-dampening materials help by absorbing vibrations and blocking sound before it reaches your living areas. These materials are typically placed under the unit, inside the housing, and along the ductwork.

The performance of these materials is measured using Sound Transmission Class (STC) values, which show how effectively a barrier reduces noise. To put it into perspective, a 10 dB increase in sound is perceived as twice as loud by most people. So, even small improvements in noise reduction can noticeably enhance your home’s comfort.

Here are three effective ways to reduce noise in AC systems.

Vibration Isolation Pads

Vibration isolation pads are designed to absorb mechanical energy, preventing noise from traveling through your home’s structure. Without these pads, the vibrations from your compressor can move through floors, walls, and ceilings, creating disruptive noise.

Materials like neoprene, rubber, cork, and spring mounts are commonly used to minimize vibration transfer. These pads are usually installed under outdoor condensers, indoor air handlers, or between wall brackets and mounting points. As Ted W from Acoustical Surfaces explains:

A series of spring isolators… will work a lot like a car’s suspension – eating up a significant amount of vibration energy.

For the best results, make sure your outdoor unit is placed on a level concrete or composite pad. An uneven surface can cause the unit to shift during operation, leading to thumping vibrations that isolation pads alone can’t fix. Additionally, using cushioned clamps and isolation grommets where refrigerant lines pass through walls can help reduce buzzing and rattling noises.

Dense Sound Barriers

Dense sound barriers are used to trap and dissipate noise directly at the source. Materials like mass-loaded vinyl (MLV), acoustical lagging, and soundproof blankets can increase the STC rating of your AC unit, effectively containing mechanical noise.

These barriers can be installed in several ways: lining the inside of the AC housing, creating external enclosures around outdoor units, or wrapping ducts. As Mary Riemenschneider from Insulation Outlook Magazine notes:

Acoustical lagging, which includes a heavy, mass-loaded vinyl, increases the STC value of the walls of the duct to significantly reduce break-in and break-out noise.

If you’re building an enclosure for an outdoor compressor, maintain at least 3 feet of clearance on all sides to allow for proper airflow and prevent overheating. For a more direct solution, custom-fitted soundproof blankets, like the BBC-EXT-TR2, can wrap around noisy compressors to absorb sound without restricting airflow.

Acoustic Insulation in Ducts

While barriers tackle noise at the source, acoustic insulation in ducts prevents sound from traveling through your home.

Ductwork often acts as a conduit for noise, carrying mechanical sounds into your living spaces. Acoustic duct insulation works by absorbing sound energy as it moves through the ventilation system.

There are two main methods: duct liners, which are installed inside the duct to absorb airflow noise, and duct wraps, which are applied to the exterior to block sound from escaping through the duct walls. Materials like recycled cotton (e.g., Quiet Liner), acoustic foam, and fiberglass wraps are commonly used. Switching from rigid metal ducts to flexible ducts with insulating layers can also reduce vibrations and airflow noise.

Before adding insulation, seal any air leaks at joints and seams with mastic or foil-backed tape – leaks can create high-pitched whistling sounds that amplify noise. For the best results, install duct silencers and liners as close to the AC unit as possible, and avoid sharp 90-degree turns in the ductwork, as these can increase turbulence and noise.

| Material Type | Function | Application |

|---|---|---|

| Isolation Pads/Mounts | Reduces structure-borne vibration | Under condensers, rooftop units, and air handlers |

| Mass-Loaded Vinyl (MLV) | Blocks airborne noise transmission | Duct lagging, interior housing lining |

| Acoustic Foam/Cotton Liners | Absorbs sound energy within airflow | Interior of ductwork, blower compartments |

| Soundproof Blankets | Blocks and absorbs compressor noise | Wrapped directly around the compressor motor |

| Flexible Ducts | Dampens vibrations and airflow noise | Transitions between rigid ductwork and vents |

Eco Temp HVAC Certified Installations for Quiet Systems

Even the most advanced noise-reduction features need expert installation to work as intended. That’s where Eco Temp HVAC’s Mitsubishi Diamond Elite Contractor certification comes in, offering homeowners across Chicagoland a level of precision that makes all the difference. This expertise ensures every noise-reducing feature performs at its best.

Eco Temp HVAC technicians are certified to fine-tune Mitsubishi’s VCSi technology, which eliminates the noisy on/off cycling common in traditional systems. Instead of abrupt starts that create loud "thumps", these systems gradually ramp up and operate at precise speeds. The result? Indoor operation as quiet as 19 dB(A) – quieter than a whisper. For comparison, traditional central air systems typically run between 70 and 75 dB.

But professional installation isn’t just about setup. Certified installers take extra steps, like using advanced vibration controls to stop mechanical hums from traveling through your home’s structure. They also perform ACCA Manual J load calculations to ensure the system is properly sized, which helps prevent noisy airflow. On top of that, outdoor units are strategically placed away from windows and reflective surfaces, keeping noise levels below strict residential ordinances – sometimes as low as 45 dB(A).

Eco Temp HVAC goes a step further by offering a 12-year extended warranty on parts and compressors for Mitsubishi ductless mini-splits, thanks to their Diamond Elite Contractor status. This warranty covers key components that contribute to quiet operation, like the inverter-driven compressor and advanced fan motors. As homeowner Randy Friedrich shared:

They’re so quiet, you hardly notice the unit running.

For Chicagoland residents dealing with extreme weather and close-knit neighborhoods, professional installation ensures your system provides both comfort and quiet. With service locations in Chicago, St. Charles, Bartlett, Lemont, Downers Grove, and Palatine, Eco Temp HVAC delivers fast, certified service throughout the region.

Conclusion

Today’s air conditioners are designed to operate with minimal noise, thanks to features like insulated compressors, variable-speed fans, inverter technology, and sound-dampening materials. These advancements can bring noise levels down from the traditional 70–80 dB range to as low as 19 dBA. This quieter operation improves sleep, enhances focus in home offices, and allows outdoor activities without disturbing the peace.

But the benefits extend beyond noise reduction. Technologies like variable-speed compressors and inverters also slash energy waste by 20–35%. Additionally, quieter systems help reduce stress and comply with strict local ordinances, such as Seattle’s 45 dBA limit.

However, even the most advanced technologies require expert installation to perform as intended. Properly installed vibration isolation pads, sealed ductwork, and well-placed outdoor units, along with fine-tuned inverter compressors, are essential to maintain quiet and efficient operation.

For homeowners in the Chicagoland area, certified Eco Temp HVAC installations provide peace of mind. With extended warranties and expert calibration, they ensure that every system is correctly sized, positioned, and maintained for lasting comfort and quiet performance.

FAQs

How do insulated compressors help reduce noise in air conditioning systems?

Insulated compressors are crafted to cut down on noise by targeting vibrations and limiting sound transmission. The insulation works by dampening the noise produced by the compressor’s internal parts, stopping it from traveling through the structure of the AC system.

By isolating vibrations and softening sound waves, these compressors play a major role in creating a quieter and more pleasant indoor atmosphere. This makes them a standout feature in today’s air conditioning systems designed to reduce noise.

How does inverter technology help make air conditioners quieter?

Inverter technology plays a big role in making air conditioning systems quieter. How? It allows the compressor to adjust its speed based on how much cooling is needed. Instead of repeatedly turning on and off at full blast, the compressor operates at variable speeds. This eliminates the loud noises often heard during start-up or when running at high speeds.

This smoother operation doesn’t just reduce noise – it also improves energy efficiency, making it a standout feature in today’s quieter, more efficient AC systems.

How does professional installation help reduce noise in air conditioning systems?

Professional installation is crucial for keeping air conditioning systems quiet by making sure everything is installed correctly. Skilled technicians know how to position the unit properly, secure all components, and use techniques like vibration isolation to cut down on unnecessary noise.

They also make sure soundproofing features – such as insulated compressors and quiet fan designs – function as intended. This careful approach not only reduces noise but also boosts the system’s efficiency and extends its lifespan.