Ductless mini-split systems are a reliable choice for commercial spaces, offering energy-efficient zone cooling and eliminating the need for ductwork. To keep these systems running efficiently and extend their lifespan, regular maintenance is key. Here’s what you need to know:

- Monthly Tasks: Clean or replace air filters every 4–6 weeks (or every 2 weeks in high-traffic areas). Inspect outdoor units for debris and ensure condensate drain lines are clear.

- Quarterly Tasks: Dust indoor unit exteriors, clean evaporator coils, and check electrical connections for wear or damage.

- Semi-Annual Tasks: Deep clean coils, blower fans, and condensate lines. Address any buildup to prevent efficiency loss.

- Annual Professional Inspection: Hire certified technicians to check refrigerant levels, test electrical components, and run diagnostics. This typically costs $300–$550 and can prevent costly repairs.

Routine care not only reduces energy bills by up to 15% but also extends the system’s lifespan from 12 to over 20 years. For high-use commercial settings, more frequent maintenance is recommended. Always turn off power before cleaning, and leave refrigerant and electrical work to professionals.

Commercial Ductless Mini-Split Maintenance Schedule and Checklist

Deep Cleaning a Ductless Mini-split System

Monthly Maintenance Checklist

Keeping up with monthly maintenance is key to ensuring your mini-split system runs smoothly. These straightforward tasks take little time but can help you avoid costly energy bills and unexpected repairs.

Clean or Replace Air Filters

Make it a habit to clean or replace your air filters every 4–6 weeks – or every two weeks if the system is in a high-traffic area. Dirty filters not only make your system work harder but also wear out its components faster. Ryan Mayes from Carrier emphasizes:

Knowing how to clean mini split filters is one of the easiest and effective ways to ensure your comfort and the efficiency of your mini split comfort system.

Before you start, always turn off the system. Carefully slide out the filters, noting their orientation so you can put them back correctly. Use a vacuum to remove surface dust or rinse washable filters if they’re heavily soiled. Make sure they’re completely dry before reinstalling them. Even with regular cleaning, plan to replace washable filters once a year to keep your system running at its best.

Once the indoor filters are sorted, shift your attention to the outdoor unit.

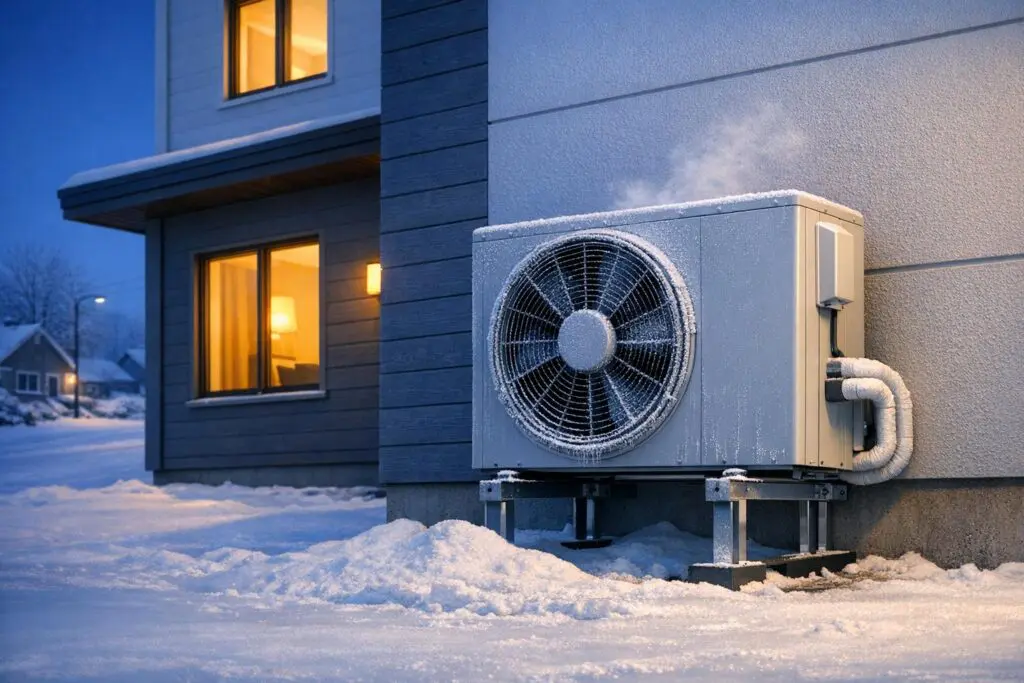

Inspect Outdoor Units for Debris

Take a moment each month to check the outdoor condenser for leaves, twigs, or other debris that might be blocking airflow. Trim back any plants or shrubs within two feet of the unit. If you notice dirt trapped between the condenser fins, gently rinse it off with a garden hose. Avoid using high-pressure washers, as they can damage the fins.

Pay attention to any unusual sounds, like rattling or grinding, which could signal debris inside the unit or an unbalanced fan blade. These small checks can prevent airflow restrictions that might otherwise lead to reduced efficiency or even compressor failure.

After cleaning the outdoor unit, make sure the system’s drainage is working properly.

Check Condensate Drain Lines

As your mini-split cools the air, moisture collects on the evaporator coil and drips into a tray that drains through tubing. Each month, inspect the drain tray and tubing for sludge, debris, or standing water. Confirm that water flows freely from the drain exits, and check nearby walls or floors for any signs of moisture buildup.

If your system relies on a condensate pump instead of gravity drainage, verify that the pump is cycling on and off as it should. Addressing drainage issues early can save you from expensive repairs caused by water damage to walls, ceilings, or floors.

These simple monthly checks go a long way in keeping your mini-split system efficient and your energy costs under control.

Quarterly Maintenance Checklist

Quarterly maintenance builds on your monthly routine by tackling tasks that focus on deeper cleaning and system checks. Every three months, take some time to address areas that accumulate dirt more gradually. These steps not only help maintain system efficiency but also catch potential issues early, saving you from costly repairs down the line.

Before starting, always turn off power to both the indoor and outdoor units to ensure safety.

Clean Indoor Unit Exteriors and Vents

Begin by wiping down the exterior cabinets and vents with a damp microfiber cloth. For tougher grime, use warm water mixed with a mild detergent, but ensure all surfaces are completely dry before turning the power back on. Use a vacuum with a soft-bristled brush attachment to clean dust from the intake and outlet vents. While you’re at it, check that no furniture, decorations, or equipment are blocking airflow to the air grills – obstructions can force the system to work harder than necessary. Also, inspect the exterior panels for any signs of cracks or corrosion that might need attention.

Inspect and Dust Evaporator Coils and Fan Wheels

Carefully open the unit cabinet and vacuum the delicate evaporator fins. Look for signs of ice build-up, oil spots, or wear that could indicate underlying problems. Use a dry cloth to clean the fan wheel, and if stubborn grime remains, apply a 1:9 bleach solution. Let it sit for about five minutes before wiping it clean. Be gentle during this process since an unbalanced fan can cause noise and mechanical issues. If you notice excessive condensation, ice, leaks, or reduced airflow even after cleaning, it’s a good idea to call in a professional technician.

Check Electrical Connections

Inspect the electrical components for any signs of discoloration, scorching, or melted insulation. Examine run capacitors for bulging or leaks, and ensure all wiring is securely fastened to avoid abrasion. Pay attention to any unusual rattling sounds, as they may indicate loose connections. Keeping these electrical parts in good shape not only ensures optimal system performance but can also help reduce energy bills by as much as 15%.

Semi-Annual Maintenance Checklist

Twice a year – preferably in spring and fall – set aside time for deep cleaning tasks that go beyond your usual monthly and quarterly maintenance. These intensive cleanings are essential to keep your commercial ductless mini-splits running efficiently and to prevent buildup that can overwork the system. As Al Chan from DiversiTech explains:

Dirt on the coils and blower wheel can quickly lead to poor output, affecting temperature and humidity control

Before starting, always turn off the power to all units and gather the necessary tools and protective gear. Then, focus on cleaning the system’s key components for optimal performance.

Deep Clean Coils and Blower Fans

Begin by removing the access panels on the indoor units to access the evaporator coils. Use a soft-bristled vacuum attachment to clear away surface dust. Follow this by applying a coil cleaner or a diluted bleach solution (the same one used in previous maintenance). Be cautious not to bend the delicate fins, but if any fins do bend, use a fin comb to straighten them. Once cleaned, consider applying a fungistat or bacteriostat treatment to prevent mold or bacterial growth.

Next, turn your attention to the blower wheel and fan. Spray these parts with the diluted bleach solution and let it sit for about five minutes. Afterward, wipe them clean with a damp cloth. To ensure proper operation, have a professional check the balance of the fan wheel.

For the outdoor condenser coils, clear away debris or vegetation within 18 inches of the unit. Use a garden hose on low pressure to gently rinse the coils, starting from the inside and working outward to avoid damaging the fins. Lastly, clean the condensate drain pan with the diluted bleach solution to prevent slime and buildup.

Clear and Treat Condensate Lines

Once the coils and fans are cleaned, move on to the condensate lines to ensure they remain clear and functional. Clogged lines can lead to water damage and create a breeding ground for mold. Start by flushing the lines with warm water. For more stubborn clogs, use the appropriate tools or cleaners to remove debris from the drain opening.

After clearing the lines, treat them to prevent future blockages. Running a diluted bleach solution through the lines works well, or you can use a non-toxic, biodegradable HVAC drain cleaner. For ongoing maintenance, consider adding water-soluble pan tablets or a monthly liquid treatment to keep the lines clear.

As Ryan Waldron from RAS Mech points out:

Commercial HVAC maintenance however, is the key to maintaining long term efficiency gains and prolonging the life of your equipment

sbb-itb-b5c10b1

Annual Professional Inspection Checklist

While regular monthly and quarterly maintenance keeps your system in good shape, scheduling an annual professional inspection is essential for commercial ductless mini-splits. These inspections, which typically cost between $300 and $550, can catch potential problems early, saving you from costly repairs down the road. Certified technicians use specialized tools to check refrigerant levels, test electrical components, and run comprehensive diagnostics, ensuring your system operates efficiently year-round.

Verify Refrigerant Levels and Check for Leaks

Refrigerant levels play a critical role in your system’s ability to heat and cool effectively. If the levels are too low, the system has to work harder, leading to higher energy bills and increasing the risk of compressor failure – one of the priciest repairs you could face. During the inspection, technicians check refrigerant lines for oil residue, a common sign of an active leak, and carefully examine flare connections for potential issues.

They also measure suction pressure, assess superheat levels, and perform a feel test on the suction line to ensure the refrigerant cycle is functioning properly. If a unit needs a refrigerant recharge, it usually indicates a leak that requires immediate attention from a certified professional. Refrigerant-related work must always be handled by trained technicians.

Test Electrical Components and System Controls

Electrical problems can shut down your system without warning, so inspecting these components is a key part of the annual checkup. Technicians examine run capacitors for bulging, leaks, or deformation – clear signs that replacement might be needed. They also inspect control boards and electrical connectors for loose connections, short circuits, or overheating. Voltage and amperage are measured for the compressor, blower, and other system components to ensure everything is operating safely.

Conduct Full System Diagnostics

After addressing refrigerant and electrical components, technicians perform full diagnostics to evaluate the system’s overall condition. One critical test involves measuring the "Delta T", or the temperature difference between the air entering and leaving the unit, to confirm the heat exchange is working efficiently. They also calibrate thermostats, assess fan performance, and check that insulation and mounting are secure. To wrap up, the blower is run to dry components, and technicians listen for any unusual noises or vibrations that could signal hidden issues. This thorough approach helps ensure your ductless mini-split remains reliable and efficient throughout the year.

Commercial-Specific Maintenance Considerations

Commercial ductless mini-split systems face unique challenges due to their heavy use. Unlike residential units, these systems often run for extended hours, serve multiple zones, and operate in high-traffic environments. This means they require more frequent and specialized care. The multi-zone setup, in particular, demands individual attention for each indoor unit. Even minor debris buildup can disrupt performance, especially in busy settings.

Regular upkeep isn’t just about keeping things running – it can also save up to 15% on energy bills. For high-usage environments, it’s recommended to clean air filters every 2–4 weeks to maintain proper airflow. As Brian Redmond, Owner of Redmond’s Complete Comfort, puts it:

They’re called mini splits for a reason – everything is micro inside of there. It does not take much for them to get dirty. The blower wheel should be pulled and cleaned at least once a year, and the drain pan needs to be cleaned and treated to prevent bacteria or mold.

DIY vs. Professional Maintenance

With the added complexity of commercial systems, it’s important to decide which maintenance tasks can be handled in-house and which require professional expertise. Basic tasks like cleaning filters, clearing debris from outdoor units, and wiping down vents can often be done by business owners or facility managers. However, more technical jobs – like addressing refrigerant issues, testing electrical components, or performing deep cleanings – should always be left to certified technicians. This ensures safety and prevents voiding the warranty.

| Task | DIY | Professional |

|---|---|---|

| Air filter cleaning/replacement | Yes | Optional |

| Clear debris from outdoor unit | Yes | Optional |

| Dust indoor unit vents/exterior | Yes | Optional |

| Condensate line treatment | Yes | Optional |

| Refrigerant leak detection | No | Yes |

| Electrical component testing | No | Yes |

| Deep clean coils & blower fans | No | Yes |

| System diagnostics | No | Yes |

Always turn off the power before performing any cleaning or inspections. Tasks like tightening electrical connections or handling refrigerant require specialized tools and certifications, so they should never be attempted without proper training. For commercial systems that see heavy use, scheduling professional maintenance every six months can help prevent energy costs from rising by 15%.

Eco Temp HVAC provides tailored maintenance services for commercial ductless mini-split systems, helping ensure your equipment stays efficient and reliable throughout the year.

Conclusion

Keeping your mini-split system in top shape involves a mix of regular DIY care and scheduled professional check-ups. Simple monthly tasks, like cleaning filters and removing debris around outdoor units, can help prevent common performance hiccups. Meanwhile, scheduling professional inspections every six months ensures that hidden technical issues are caught early. Together, these steps can extend your system’s lifespan to an impressive 15–20 years.

When it comes to cost, routine maintenance is much more affordable than emergency repairs or premature replacements. Professional servicing for mini-split systems typically ranges from $150 to $500 per visit, depending on the number of indoor units. As Lennox puts it:

The minimal cost of a check-up or a tune-up is definitely preferable to that of a costly repair that could have been avoided.

By staying on top of maintenance, you’ll not only avoid unnecessary expenses but also enjoy better efficiency, improved air quality, and consistent temperature control.

For those in the Chicagoland area, Eco Temp HVAC provides expert maintenance services tailored to commercial ductless mini-split systems. Their certified technicians handle everything from diagnostics and component cleaning to refrigerant checks and electrical testing, ensuring your system operates at peak efficiency. As a Mitsubishi Diamond Elite Contractor, they even offer a 12-year warranty on qualifying Mitsubishi products.

Make it a habit to schedule professional maintenance twice a year – ideally before the busiest heating and cooling seasons – to keep your system running smoothly.

FAQs

How often should commercial ductless mini-split systems be maintained?

To ensure your commercial ductless mini-split system works efficiently and lasts longer, it’s crucial to stick to a regular maintenance schedule. Experts recommend scheduling professional maintenance twice a year – once in the spring (March or April) before the cooling season kicks in, and again in the fall (September or October) before heating becomes necessary. On top of that, monthly filter checks and cleanings by your team are key to maintaining proper airflow and good indoor air quality.

Here’s a simple maintenance plan to keep your system running smoothly:

- Biannual professional service: A technician will check refrigerant levels, clean the coils, inspect electrical connections, and ensure the system is operating as it should.

- Monthly filter care: Clean or replace filters regularly. You can vacuum or wash them to avoid clogs that restrict airflow.

- Quarterly outdoor unit check: Remove debris, leaves, and vegetation within an 18-inch radius of the outdoor unit to keep the condenser coil clear.

Following this routine can help lower energy bills, prevent expensive repairs, and enhance air quality in your commercial space. If you’re in the Chicagoland area, Eco Temp HVAC has certified technicians ready to handle your professional maintenance needs and keep your system running at its best.

What are the warning signs that my ductless mini-split system needs professional service?

If your ductless mini-split system isn’t working as it should, there are some telltale signs that it might need a professional checkup. Pay attention to unusual noises like rattling or buzzing, as these could signal internal issues. A drop in heating or cooling performance is another red flag, along with water leaks or clogged drain lines. You might also notice unpleasant odors or even ice forming on the indoor coil, both of which point to potential problems. And don’t ignore error codes on your thermostat or control panel – they’re your system’s way of telling you something’s wrong. Tackling these issues early can help you avoid bigger headaches and keep your mini-split running smoothly.

Can I maintain my ductless mini-split system myself, or should I hire a professional?

You can take care of some basic upkeep for your ductless mini-split system, like cleaning the filters on the indoor unit, dusting the cabinet, and clearing debris from around the outdoor condenser. Performing these tasks on a monthly or quarterly basis helps keep the system running smoothly and ensures proper airflow. That said, leave the more technical jobs – such as refrigerant level checks, electrical inspections, or coil cleaning – to a licensed HVAC technician. Attempting these on your own could lead to safety hazards, system damage, or even void your warranty.

For commercial systems, professional maintenance is even more essential. These systems are larger and more intricate, requiring specialized expertise for proper calibration, servicing, and ensuring they meet warranty requirements. Eco Temp HVAC provides certified maintenance services for commercial ductless mini-splits throughout the Chicagoland area. Their trained technicians are available 24/7 to help keep your system operating at peak efficiency.