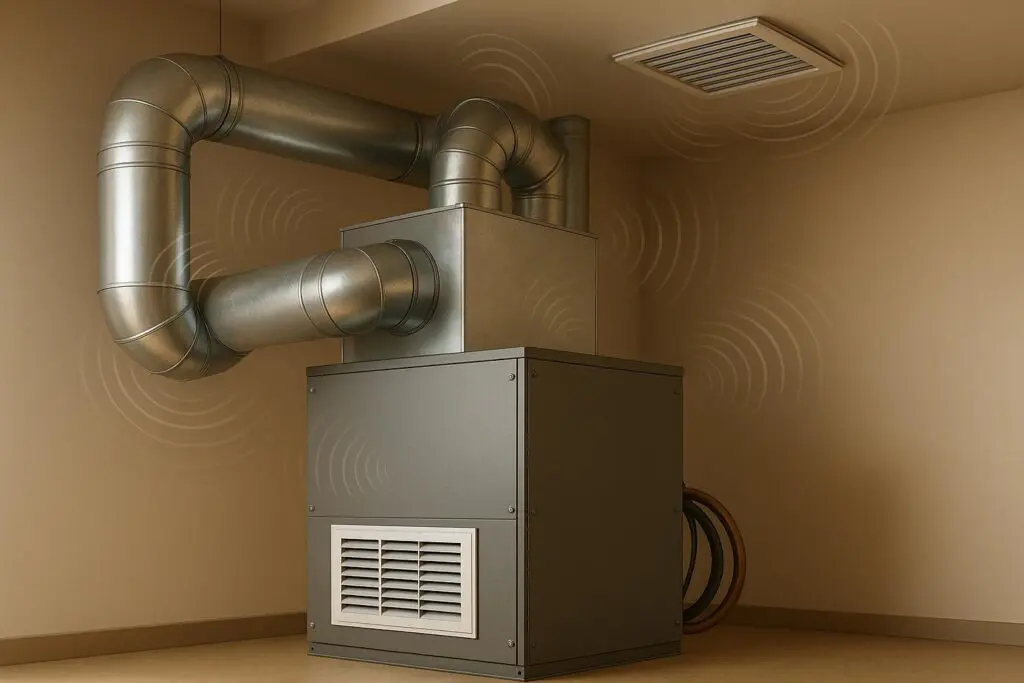

HVAC systems are designed to run quietly, but unusual noises like banging, rattling, or hissing often signal underlying problems. Ignoring these sounds can lead to higher energy bills, reduced comfort, or even safety hazards. Here’s a breakdown of common HVAC noises, their causes, and what you should do:

- Banging or Clanking: Likely caused by loose parts, ductwork issues, or serious mechanical problems. Shut off the system and call a technician.

- Rattling or Vibrating: Often due to loose screws, unbalanced blower wheels, or poorly supported ductwork. Tighten parts or seek professional help if the issue persists.

- Squealing or Screeching: Usually indicates worn belts or motor issues. Schedule service promptly to avoid further damage.

- Hissing or Whistling: Could mean airflow blockages, duct leaks, or refrigerant leaks. Loud, continuous hissing requires immediate attention.

- Buzzing or Humming: Points to loose components or electrical problems like failing capacitors. Electrical issues should always be handled by a professional.

- Clicking or Tapping: Normal during startup, but repeated clicking may signal electrical or thermostat issues.

- Gurgling, Bubbling, or Dripping: Tied to condensate drainage problems or refrigerant issues. Clear drain lines or consult a technician if the noise persists.

Quick Comparison

| Noise | Common Causes | Urgency | Action |

|---|---|---|---|

| Banging or Clanking | Loose parts, duct issues, compressor | Immediate | Shut off and call a technician. |

| Rattling or Vibrating | Loose screws, unbalanced parts | Monitor or Schedule Service | Tighten parts, call if unresolved. |

| Squealing or Screeching | Worn belts, motor issues | Schedule Service | Address before it worsens. |

| Hissing or Whistling | Airflow blockages, refrigerant leaks | Immediate if severe | Replace filters, call for leaks. |

| Buzzing or Humming | Loose components, electrical issues | Schedule Service | Avoid DIY, call a professional. |

| Clicking or Tapping | Relays, loose parts, ignition issues | Monitor or Schedule Service | Check for loose parts, call if needed. |

| Gurgling or Dripping | Drainage or refrigerant problems | Schedule Service | Clear drains, consult a technician. |

If your HVAC system is acting up, don’t wait. Strange noises often mean bigger problems down the line. Regular maintenance can prevent these issues and save on costly repairs. For immediate help, contact a certified technician. </article>

1. Banging or Clanking

Noise Description and How It Sounds to Homeowners

Banging or clanking sounds are hard to miss. Imagine the sharp, metallic impact of a hammer hitting metal – that’s the kind of noise we’re talking about. For homeowners, these sounds can be startling, often making it impossible to ignore.

These noises typically come from the indoor air handler, outdoor condenser, or ductwork. Sometimes, it’s just one loud bang as the system starts up; other times, it’s a continuous clanking while the unit is running. Homeowners may also notice a "popping" sound from the ducts, caused by thin metal flexing as air pressure changes.

Most Likely Causes of the Noise

Here’s what might be behind those unsettling sounds:

- Loose or misaligned components: A blower wheel that’s out of balance can hit its housing, creating loud bangs. Similarly, bent or broken fan blades may strike nearby parts. If the blower or condenser fan motor shifts from its mounts, rotating parts can collide with the cabinet. Even loose access panels, brackets, or unsecured refrigerant and drain lines can vibrate violently, producing noise.

- Ductwork issues: Thin, poorly supported ductwork is a common culprit. When supply registers are blocked or closed, or when an updated high-efficiency system forces more air through older ducts, the thin sheet metal can flex and pop due to pressure changes. This is especially common in unconditioned spaces like attics or crawlspaces, where temperature swings cause the metal to expand and contract.

- Serious mechanical problems: A failing outdoor compressor, damaged blower assembly, or major internal components coming loose can lead to persistent banging. Additionally, scale buildup in heat exchangers may block water flow, causing boiling and steam expansion that sounds like a kettle banging.

These issues aren’t just annoying – they’re warnings of potential damage that shouldn’t be ignored.

Urgency of the Issue

When it comes to banging sounds, quick action is key. While occasional duct popping in older systems might not require immediate attention, most banging noises indicate mechanical problems that could worsen if left unchecked.

Before calling a professional, here are a few things you can do safely:

- Turn off the system’s power at the breaker or disconnect switch.

- Inspect the area around the indoor and outdoor units for loose screws, debris, or items vibrating against the cabinet.

- Ensure vents are open and not blocked by furniture.

- Check the air filter and replace it if it’s dirty, as restricted airflow can create pressure issues that lead to duct noises.

However, if the banging is severe or persistent, shut the system off immediately. This is especially important if the noise is continuous, starts suddenly, or comes with other warning signs like burning smells, weak airflow, tripped breakers, or visible shaking of the outdoor unit.

Ignoring these signs can result in serious consequences, including complete system failure, costly repairs like compressor or blower replacement, and even electrical hazards. Repair costs for banging issues typically range from $100 to $300.

Preventing Future Issues

Routine maintenance is your best defense against banging noises. During annual tune-ups, a technician will:

- Tighten electrical connections and mounting hardware.

- Inspect and clean the blower wheel and fan blades.

- Check motor mounts and bearings.

- Verify refrigerant levels and airflow.

- Examine ductwork and supports for potential issues.

If you’re dealing with banging sounds, keeping a noise log can help your technician diagnose the problem more efficiently. Write down when the noise occurs, how long it lasts, whether it happens during startup, operation, or shutdown, and whether the system is in heating, cooling, or fan-only mode. Include details like where the noise is loudest, the outdoor temperature, and any recent changes like filter replacements or thermostat adjustments.

For homeowners in the Chicagoland area, companies like Eco Temp HVAC can quickly identify and resolve banging noises. Whether it’s loose parts, motor issues, or ductwork problems, their expertise with systems like Mitsubishi and Navien ensures accurate fixes that align with manufacturer standards. This is especially helpful if you’re thinking about upgrading an older, noisy system to better handle the region’s climate.

2. Rattling or Vibrating

Noise Description and How It Sounds to Homeowners

Rattling or vibrating noises can range from a soft, persistent metallic chatter to a more pronounced shaking or buzzing. Homeowners often describe these sounds as a "metal-on-metal" clatter or a vibration that seems to ripple through walls and floors.

These noises are typically heard near the outdoor condenser unit, around the indoor air handler or furnace cabinet, or even through exposed ductwork and vents. Sometimes, the vibration from poorly connected or undersized ductwork can make the sound feel like it’s coming from walls, ceilings, or vents.

One of the simplest culprits? Small debris like twigs, leaves, or stones entering the outdoor unit. These can strike the fan blades or housing, creating a rattling sound. In such cases, removing the debris usually resolves the issue.

Most Likely Causes of the Noise

Rattling or vibrating sounds often develop over time due to wear, installation issues, or external factors. Here are some common causes:

- Loose mechanical parts: Screws that have worked loose, unbalanced blower wheels, or bent fan blades are frequent offenders. Even a slightly unbalanced blower wheel in the indoor air handler can send vibrations rippling through the system, making the issue seem worse than it is.

- Installation and mounting issues: Improper leveling, weak mounting, or refrigerant and drain lines touching the structure can transmit vibrations. Poorly supported metal ductwork may also flex and knock against joists, especially in high-efficiency systems that move air at higher pressures.

- Electrical problems: A rapid, metallic chattering sound during startup might point to a failing contactor or relay. This can be an early sign of electrical issues, such as loose connections or problems with low-voltage controls.

- Ductwork and vent issues: Return air grilles and supply registers can rattle if they’re not securely fastened or if high airflow causes thin metal components to vibrate.

Urgency of the Issue

How urgently you need to address rattling sounds depends on their intensity and frequency. A light, occasional rattle during startup that fades quickly might indicate something minor, like a loose vent or small debris, which can wait until your next maintenance appointment.

However, persistent or loud vibration – especially if accompanied by cabinet shaking, burning smells, or tripped breakers – could signal more serious problems. These might include damaged blower components, bent fan blades, or mounting issues that need immediate attention. Ignoring these signs can lead to accelerated wear on motors and compressors, resulting in costly repairs.

Before calling a technician, turn off the power and check for loose screws, debris, or unstable vents. Replacing a clogged air filter can also help, as restricted airflow increases pressure and can worsen vibrations. However, avoid tampering with sealed electrical compartments or internal components – this could be dangerous and might void your warranty.

If the noise persists or you notice additional warning signs like burning smells or electrical issues, it’s time to call a certified technician. Prolonged rattling can lead to broken fan blades, damaged blower wheels, loosened electrical connections, or even premature motor or compressor failure. These issues not only increase repair costs but can also cause uneven temperatures and drafts in your home.

A professional technician will inspect the system thoroughly, checking for loose panels, unbalanced blower and fan assemblies, improper mounting, and electrical or refrigerant line issues. Depending on the problem, common repairs might include tightening or replacing mounting hardware, rebalancing blower wheels or fan blades, installing vibration-isolating pads, or securing loose lines and ducts. Diagnostic visits typically cost between $80 and $150, while repairs can range from $150 to $600, depending on the severity.

For homeowners in the Chicagoland area, Eco Temp HVAC offers expert diagnostics and solutions for rattling and vibration issues. Their certified technicians can address problems like improper mounting, airflow imbalances, or system sizing. In areas like Chicago, where seasonal temperature swings can loosen fasteners over time, regular inspections help prevent these issues from escalating.

To reduce the chances of future rattling, follow these tips:

- Replace filters as recommended by the manufacturer, usually every one to three months.

- Keep the area around the outdoor unit clear of debris and vegetation.

- Avoid blocking too many supply vents to maintain proper airflow.

Scheduling professional maintenance once or twice a year – ideally before the heating and cooling seasons – allows a technician to catch early signs of vibration and keep your system running smoothly. Regular upkeep can save you from major repairs down the line.

3. Squealing or Screeching

Noise Description and How It Sounds to Homeowners

Squealing or screeching sounds are unmistakable – high-pitched, sharp, and either continuous or intermittent. They often resemble the sound of a slipping belt or even a chirping bird. Homeowners typically notice these noises coming from the blower motor inside the house or the outdoor condenser unit. The sound tends to be most noticeable when the system starts up, but in more severe cases, it can linger throughout operation. Some describe it as an ear-piercing screech that cuts through everyday household noise, while others hear a high-frequency whine that varies with the system’s activity.

A quick squeal lasting just a second or two when the system kicks on might be normal for certain older systems, especially those with belt-driven components. However, if the noise is getting louder, lasting longer, or happening more often, it’s a sign of a mechanical issue that needs attention. Let’s take a closer look at what might be causing these sounds.

Most Likely Causes of the Noise

The specific cause of squealing depends on whether your system uses a belt-driven or direct-drive blower motor.

Belt-driven blower systems are a common source of squealing. Over time, the blower belt can wear out, fray, or lose tension, preventing it from gripping the pulleys effectively. This slippage creates the characteristic squealing noise. These belts endure constant friction and temperature fluctuations, which cause them to degrade. In humid regions, moisture can further weaken the belt, reducing its lifespan. Typically, blower belts last between 5 and 10 years, depending on usage and maintenance.

Misaligned belts are another frequent issue. If the pulleys aren’t properly aligned or if mounting hardware becomes loose, the belt can rub against the edges of the pulleys. This not only produces noise but also causes uneven wear, leading to premature failure.

Direct-drive systems, which are more common in modern HVAC setups, don’t use belts. Instead, squealing in these systems often points to motor bearings that need lubrication or have begun to wear out. Bearings allow the motor shaft to spin smoothly, but if they dry out or collect debris, the resulting metal-on-metal contact produces a high-pitched screech.

In outdoor condenser units, fan motor issues can also cause screeching. Bearings in the fan motor may lack lubrication, or the motor itself could be failing. Seasonal temperature changes and the demands of high-efficiency systems can increase stress on these components, making worn bearings more likely to squeal under load.

Sometimes, the problem isn’t the mechanical components themselves but how they’re installed. Poor installation – such as uneven mounting or inadequate insulation – can amplify normal operational sounds, making them seem much louder. In such cases, a professional technician can correct the setup to reduce noise.

Urgency of the Issue

While squealing or screeching isn’t an emergency, it’s not something to ignore. Operating a system with worn or failing components can reduce efficiency and lead to more extensive damage over time.

If the noise is brief and hasn’t changed over time, you can likely wait until your next scheduled maintenance appointment. However, persistent or worsening squealing should be addressed promptly. Running the system with a worn belt, for example, risks the belt snapping entirely, which would disable the blower and leave you without heating or cooling.

To start, check where the noise is coming from and ensure your air filter is clean. A clogged filter can restrict airflow, which might worsen the noise. Inspect the outdoor unit for loose hardware or debris that could be contributing to the problem.

If the noise continues, professional repairs are likely needed. These might include replacing a worn belt, lubricating bearings, or realigning motors and pulleys.

Call an HVAC technician if:

- The squealing persists after basic troubleshooting.

- The noise is accompanied by reduced heating or cooling performance.

- The sound is loud enough to disrupt daily activities.

- You detect burning smells or see visible smoke (turn off the system immediately).

- You’re unsure of the cause, especially with older systems.

A technician will thoroughly inspect components like the blower motor, belts, bearings, and outdoor fan motor. Common fixes include replacing a worn belt, lubricating or replacing bearings, realigning pulleys, or tightening mounting hardware. While belt replacements are relatively affordable, bearing repairs or motor realignment can be pricier. If the blower motor itself fails, repair costs can climb significantly. Diagnostic visits generally cost $80 to $150, with repair costs varying based on the issue.

For residents in the Chicagoland area, Eco Temp HVAC offers prompt and reliable service. In places like Chicago, St Charles, Bartlett, and Palatine, where extreme seasonal temperatures put extra strain on HVAC systems, regular maintenance is especially important to catch these problems early.

Preventive Maintenance Tips

Preventing squealing issues starts with regular maintenance. Schedule professional HVAC service at least once a year – ideally before the heating or cooling season begins. During these visits, technicians will inspect and lubricate blower motor bearings, check belt tension and condition, align components, and clean the outdoor condenser unit.

Between professional visits, keep your system in good shape by:

- Replacing your air filter every one to three months to ensure proper airflow.

- Clearing debris and vegetation from around your outdoor unit to avoid fan motor issues.

Staying on top of maintenance not only prevents annoying noises but also extends the life of your equipment and keeps it running efficiently. Addressing squealing early can save you from unexpected breakdowns and costly emergency repairs later on.

4. Hissing or Whistling

Noise Description and How It Sounds to Homeowners

Hissing or whistling noises often sound like air escaping from a tire or a kettle. These sounds can come from supply vents, return grilles, the air handler, or even the outdoor condenser. They might be constant or occur off and on, and their location can shift. Paying attention to when and where the noise happens can help narrow down the issue.

Sometimes, a faint whistle at startup is just air moving through slightly restricted ductwork. But if you hear a loud, continuous hiss – especially one that seems urgent – it could point to a more serious problem. Let’s break down the most common reasons behind these sounds.

Most Likely Causes of the Noise

Hissing or whistling noises usually stem from a few typical problems:

- Airflow restrictions: Dirty filters or blocked vents can restrict airflow, leading to whistling sounds.

- Ductwork issues: Leaky or improperly sized ducts can let conditioned air escape into spaces like attics or walls, creating a hissing noise. Undersized or damaged ductwork can make the sound even worse.

- Refrigerant leaks or high pressure: Refrigerant leaks not only reduce cooling efficiency but can also pose health risks. If the compressor’s internal pressure gets too high, the pressure relief valve might release refrigerant, producing a loud, urgent hiss. This is a sign that the system is under serious stress and needs immediate attention.

Urgency of the Issue

As with other HVAC noises, hissing or whistling can signal underlying problems that range from minor to critical. How quickly you need to act depends on the source and intensity of the sound:

- Minor issues: A clogged filter or blocked vent is usually easy to fix by replacing the filter and clearing obstructions from the vents.

- Moderate issues: Duct leaks might not cause immediate system failure, but they can waste energy and make your home less comfortable. Professional duct sealing typically costs between $300 and $1,000.

- Urgent issues: A loud, continuous hiss – especially from the outdoor unit – could mean a refrigerant leak or dangerously high internal pressure. If this happens, turn off your system and call a professional right away. For example:

In 2022, a suburban homeowner experienced loud hissing and system failure due to a refrigerant leak in the AC compressor. Repairs cost $1,200, and the technician recommended annual maintenance to avoid future leaks (American Standard Air, 2022).

Refrigerant leak repairs generally cost between $200 and $1,500. Tackling these problems quickly can help you avoid further damage and bigger repair bills.

Call an HVAC technician immediately if:

- The hissing is loud, continuous, and coming from the outdoor unit.

- You notice reduced heating or cooling performance along with the noise.

- Ice is forming on refrigerant lines or the outdoor coil.

- The noise comes with strange odors.

- Basic fixes like replacing filters or clearing vents don’t resolve the issue.

- The noise gets louder over time.

In areas like Chicagoland, where extreme seasonal temperature swings put extra stress on HVAC systems, these problems can escalate quickly. Eco Temp HVAC provides 24/7 emergency service in Chicago and nearby areas, including St. Charles, Bartlett, Lemont, Downers Grove, and Palatine. Their certified technicians can diagnose whether the hissing is due to a simple duct issue or a more serious refrigerant leak, ensuring your system is repaired safely and efficiently.

To keep your system running smoothly between professional visits, replace filters every one to three months, keep vents clear, and schedule annual maintenance. Addressing these warning signs early will help your HVAC system perform at its best.

5. Buzzing or Humming

Noise Description and How It Sounds to Homeowners

Buzzing or humming noises from an HVAC system can be a sign of potential trouble. These sounds often resemble the steady, low-pitched vibration of an electrical transformer. Homeowners typically hear this noise near the outdoor condenser unit, especially when the fan or compressor is trying to start. However, it can also come from the indoor air handler, return vents, or even the thermostat if there’s an electrical issue in the control wiring or relays.

A soft, consistent hum is usually normal. But if the noise gets louder, becomes irregular, or continues even when the system is off, it’s time to take a closer look. Changes in tone or persistence could point to a problem, often accompanied by warning signs like reduced airflow, warm air instead of cool, or circuit breakers that trip repeatedly.

Most Likely Causes of the Noise

Buzzing or humming sounds often stem from either mechanical vibrations or electrical problems. Knowing the difference can help determine how urgent the issue is.

- Mechanical causes are usually simpler to address. Loose sheet-metal panels, brackets, or screws can vibrate when the blower or condenser fan runs. Over time, normal wear and tear can loosen hardware, and dirt buildup on fan blades can throw them off balance. Worn fan motors or blower assemblies with failing bearings can create similar noises. Even refrigerant lines that aren’t properly secured can vibrate against other components, especially when the system is working hard during extreme weather.

- Electrical causes tend to be more serious. Buzzing can be linked to failing components like contactors, relays, transformers, or capacitors. For instance, a contactor coil that doesn’t fully engage, a weak capacitor struggling to start a motor, or loose wiring at terminals can all produce a persistent electrical buzz. These issues can lead to overheating, arcing, or tripped safety devices, increasing the risk of component failure or even fire.

Understanding these causes helps you decide whether it’s something you can troubleshoot yourself or if professional help is needed.

Urgency of the Issue

Buzzing or humming noises generally fall somewhere in the middle of the urgency scale. They’re not as alarming as loud banging, but they’re more concerning than a light rattle. The key is figuring out whether it’s a minor vibration issue or a serious electrical problem.

- Minor issues you can address yourself include debris near the outdoor condenser, such as twigs or leaves touching the fan guard or housing. Turn off the power at the disconnect or breaker, then check for and tighten any loose panels or screws. Once you restore power, listen to see if the noise has changed. Replacing a dirty air filter, ensuring vents are open and unobstructed, and securing loose registers can also help.

- Urgent issues demand immediate attention. If the outdoor unit hums loudly but the fan or compressor doesn’t start, shut off the system and call a technician. Other red flags include buzzing paired with burning smells, sparks, smoke, or overheated components. Frequent breaker trips or rapid on-off cycling are also signs of serious electrical or mechanical problems.

Common fixes include tightening loose parts, replacing worn motors or electrical components like contactors and capacitors, or scheduling professional maintenance. If the noise is caused by airflow or duct vibration, technicians might add supports, insulation, or dampers to reduce the sound.

Eco Temp HVAC provides full-system inspections and repairs across Chicagoland. Their certified technicians quickly diagnose and address issues, following manufacturer-recommended solutions. With 24/7 availability, they’re ready to help when you need it most.

To avoid future buzzing or humming, especially in older systems, schedule regular tune-ups. During these visits, technicians can tighten electrical connections, check capacitors and contactors, lubricate motor bearings, and ensure fan blades and blower wheels are clean and balanced. Keep your outdoor unit clean and level, secure refrigerant lines, and maintain clean filters and open vents to reduce vibration and noise. Routine maintenance is essential for preventing these problems and keeping your system running smoothly.

6. Clicking or Tapping

Noise Description and How It Sounds to Homeowners

Clicking or tapping sounds are often compared to the click of a ballpoint pen. Homeowners usually notice this noise when their HVAC system starts up or shuts down, though it may also occur in a steady rhythm while the system is running.

The location of the clicking can give clues about its source. You might hear it near the thermostat, inside the furnace closet or air handler, at the outdoor condenser unit, or even in walls and ceilings where ductwork runs. A single click or brief series of clicks when your thermostat calls for heating or cooling is typically normal. It’s the sound of relays, contactors, or the control board engaging to adjust to the set temperature.

Tapping noises from ductwork are also common in many U.S. homes, especially those with long runs of sheet metal ducts. When warm or cool air flows through the ducts, the metal expands or contracts due to temperature changes, causing popping or tapping sounds. This is more noticeable during seasonal transitions between heating and cooling or within the first few minutes of system operation. However, repeated or unusual clicking often points to a deeper issue.

Most Likely Causes of the Noise

Normal clicking during operation usually comes from control relays engaging. This includes the thermostat relay switching on and off, contactors starting the compressor or blower, and the control board activating various components. Heat pumps may add extra clicks when switching between heating and cooling modes or entering defrost mode.

On the other hand, problematic clicking often stems from loose or worn parts. Examples include:

- Loose components: Blower fan blades, screws, or access panels that aren’t secured can create repetitive tapping as the fan spins.

- Worn bearings: Bearings in the blower or fan motor may cause rhythmic tapping or clicking that speeds up as the fan runs faster.

- Ductwork issues: Tapping sounds from ducts during startup or shutdown could indicate undersized or poorly supported ductwork shifting with air pressure changes.

Electrical issues can also cause more concerning clicking noises. Failing relays, malfunctioning thermostats, or defective contactors may lead to rapid or repeated clicking as the system struggles to start key components like the compressor or blower. In gas furnaces, repeated clicking near the burner area often signals ignition problems, which can result in hard starts, short cycling, or even system failure. These issues may pose overheating or fire risks if left unaddressed.

Urgency of the Issue

The urgency of addressing a clicking noise depends on its severity and impact.

- Minor issues to monitor: Occasional soft clicks during startup and shutdown that don’t affect comfort or energy usage are usually not urgent. Similarly, duct tapping or popping that fades after a minute or two can be addressed during routine maintenance to improve comfort and reduce noise. Before calling a technician, check your thermostat settings, replace a dirty air filter, and ensure access panels are securely fastened. Walk around to pinpoint the noise source and check for loose grilles or vents.

- When to call a technician: If rapid clicking is accompanied by system failure, burning smells, or tripped breakers, immediate action is needed. Repeated unsuccessful ignition attempts in a gas furnace also require prompt attention. In these cases, turn off the system and contact a licensed HVAC technician.

Eco Temp HVAC provides fast, reliable service across Chicagoland, with certified technicians available 24/7 to diagnose whether the clicking is part of normal operations, a sign of loose components, or an indication of failing electrical parts. Their comprehensive heating and cooling services ensure both the noise and any underlying issues are addressed in one visit.

Preventative maintenance is key to avoiding persistent clicking. Regular tune-ups should include inspecting electrical connections, contactors, and relays; lubricating moving parts; and checking fan assemblies. Keeping air filters clean, ensuring vents are unobstructed, and trimming vegetation around the outdoor unit can also help prevent debris-related tapping and reduce strain on the system. When describing the noise to a technician, be sure to note where it seems to come from, when it occurs, and whether the system is heating or cooling properly – this can speed up the diagnosis and save on labor time.

sbb-itb-b5c10b1

7. Gurgling, Bubbling, or Dripping

What These Sounds Mean

If you’ve ever heard gurgling, bubbling, or dripping noises coming from your HVAC system, you’re not alone. These sounds often mimic the gentle flow of water or the occasional drip of droplets. They’re typically most noticeable near the indoor unit, where condensate drainage happens, or around the outdoor condenser when the system is in cooling mode.

Why It Happens

These sounds are usually tied to the system’s condensate drainage process. As your HVAC system works to remove moisture from the air, the water drains through specific lines and pans. A partially blocked drain line can amplify these noises, making the flow of water more noticeable.

While an occasional gurgle or drip is often nothing to worry about, louder or more persistent noises can signal a potential issue. It’s important to keep an ear out for changes in these sounds.

When to Call in the Experts

Minor drainage sounds are normal, but if the gurgling, bubbling, or dripping becomes constant or unusually loud, it’s time to take action. Pay close attention to signs like water pooling around the unit or visible moisture buildup – these could indicate a clogged or malfunctioning drainage system.

In many cases, clearing the drain lines can resolve the issue. However, if the problem persists or worsens, it’s best to have a professional inspect the system. Ignoring these noises could lead to bigger problems down the line.

For homeowners in the Chicagoland area, Eco Temp HVAC’s certified technicians are ready to help. They can assess your system’s drainage components to ensure everything is running smoothly. Regular maintenance, including checking the drainage system, is key to catching small issues before they turn into major headaches.

Why is My HVAC Making Noise? | Weird HVAC Noises (or Smells!)

When to Call a Professional

If your HVAC system starts making unusual noises, it’s often a sign that something’s not quite right. Ignoring these sounds could turn minor issues into expensive repairs. Catching them early makes all the difference.

Certain noises demand immediate attention. For instance, banging or clanking often means there are loose or broken components inside the system that need professional repair. Squealing or screeching could point to problems with a belt or motor, while a hissing sound might signal a refrigerant leak that requires specialized handling. Buzzing or clicking noises linked to electrical issues should always be addressed by a licensed technician to avoid safety hazards. And if noises are accompanied by water leaks, ice buildup, or a complete system breakdown, it’s time to call in an expert – fast.

For all these issues, Eco Temp HVAC offers comprehensive diagnostic and repair services, available 24/7. Their team of certified professionals includes American Standard Customer Care dealers, Navien Service Specialists, and Certified Mitsubishi Diamond Elite Contractors. Whether it’s a small fix or a major system failure, they’ve got the skills and tools to get your HVAC system back on track.

"Our technicians are available day or night, 24/7. When you have a heating and cooling issue, our pros are there to come to your rescue."

Eco Temp HVAC serves areas like Chicago, Lemont, St. Charles, Bartlett, Palatine, and Downers Grove, ensuring quick response times no matter where you are. Whether it’s a noisy furnace on a freezing winter night or an air conditioner acting up during a summer heatwave, their team is ready to help.

They also pride themselves on upfront pricing, so you won’t face any surprises. Their technicians will pinpoint the source of the noise, explain the issue in detail, and offer solutions to restore your system’s quiet and efficient operation. Regular maintenance services are also available to help prevent noise-related problems and keep your HVAC system running smoothly throughout the year.

Don’t let persistent noises lead to bigger, costlier repairs. Get your system checked by a professional without delay.

Noise Comparison Table

The table below is your quick guide to identifying HVAC system noises and deciding on the next steps. It ties back to the detailed explanations provided earlier, helping you understand when it’s time to call in a professional.

| Noise Type | Common Causes | Urgency Level | Recommended Action |

|---|---|---|---|

| Banging or Clanking | Loose or misaligned components | Shut Down Immediately | Turn off your system right away and contact a certified technician. |

| Rattling or Vibrating | Loose or unsecured components (e.g., screws or panels) | Monitor | Check for loose parts and tighten any exposed connections. If the noise persists, schedule professional service. |

| Squealing or Screeching | Worn or loose belts, motor issues | Schedule Service | Startup squeals may be normal, but continuous high-pitched sounds signal belt or motor problems. Schedule an inspection soon. |

| Hissing or Whistling | Airflow issues (e.g., refrigerant leaks, duct gaps, or blocked vents) | Schedule Service (Immediate if refrigerant leak detected) | Replace the air filter and ensure vents are open. If the noise persists, especially if it resembles a refrigerant leak, call a licensed technician immediately. |

| Buzzing or Humming | Loose electrical connections or failing electrical components (e.g., capacitor) | Schedule Service | Electrical buzzing can pose safety risks. Avoid DIY fixes and contact a professional to inspect and repair the electrical system. |

| Clicking or Tapping | Thermostat or relay issues | Monitor | Occasional clicks during startup or shutdown are normal. Continuous or rapid clicking may indicate electrical or thermostat issues – schedule service if it persists. |

| Gurgling, Bubbling, or Dripping | Condensate drain blockage or refrigerant issues | Schedule Service | Check the condensate drain for clogs. Persistent water-related sounds could lead to damage and should be handled promptly by a professional. |

Understanding the Urgency Levels:

- Shut Down Immediately

Turn off your system and call for emergency service right away. - Schedule Service

Arrange professional repairs within a few days to a week. Ignoring these noises could lead to system failure or expensive repairs. - Monitor

Start with basic troubleshooting. If the noise doesn’t improve or worsens after a day or two, reach out to a professional.

Keep in mind that seasonal temperature changes can sometimes cause temporary system noises. However, if the sounds persist, it’s best to have them checked out. Regular inspections go a long way in preventing minor issues from turning into major problems.

Eco Temp HVAC proudly serves the Chicagoland area, offering quick response times for both routine maintenance and emergency services.

Conclusion

Your HVAC system has its own way of communicating, often through the sounds it makes. Ignoring unusual noises can transform a simple repair into a costly replacement. Tackling these issues promptly, as discussed earlier, helps keep your system running efficiently, which can mean noticeable savings on your monthly utility bills. More importantly, addressing problems early ensures your home or business remains comfortable through Chicago’s freezing winters and humid summers.

Small issues have a way of escalating quickly. Professional repairs not only prevent these problems from spiraling out of control but also protect the investment you’ve made in your heating and cooling system. Acting quickly preserves performance and avoids unnecessary wear and tear.

While some noises might seem easy to handle – like tightening a loose panel or swapping out an air filter – more complex problems demand professional attention. Persistent electrical buzzing, loud banging, or potential refrigerant leaks are not DIY fixes. These situations require certified technicians equipped with the proper tools and expertise to diagnose and resolve the problem safely.

For residents in Chicagoland, Eco Temp HVAC offers expert service 24/7, with certified technicians ready to handle any HVAC system. Whether you need same-day repairs or want to schedule preventive maintenance to head off future issues, their team is available around the clock. Plus, when you call, you’ll always speak with a live person at their on-site call center, and they provide free quotes for all services.

If your HVAC system starts making strange noises, don’t wait. Prompt repairs save money, prevent further damage, and ensure your comfort all year long.

FAQs

Why is my HVAC system making a loud banging noise, and what should I do?

If your HVAC system is making a loud banging noise, it’s usually a sign that something’s wrong – possibly a loose or broken part in the blower assembly or compressor. This type of noise might also point to an imbalance in the system’s components, which, if ignored, can cause even more damage over time.

To avoid expensive repairs and keep your system running safely, reach out to Eco Temp HVAC. Their certified technicians are experts at pinpointing and resolving HVAC issues fast, so your heating and cooling system can get back to working seamlessly.

What does it mean if my HVAC system is making a hissing noise?

A hissing sound coming from your HVAC system often signals a problem, with one of the most frequent culprits being a refrigerant leak. Since refrigerant plays a key role in cooling, any leak can lower your system’s performance, drive up energy bills, and potentially lead to more serious damage if left unchecked.

Other reasons for the hissing noise might include air escaping through a damaged duct or issues with the expansion valve. Whatever the cause, it’s crucial to address it quickly to prevent bigger headaches down the road. Reach out to a professional HVAC technician, like the certified team at Eco Temp HVAC, to diagnose and fix the problem safely.

Why should I address buzzing or humming noises from my HVAC system right away?

Strange buzzing or humming noises coming from your HVAC system might seem like a minor annoyance, but ignoring them can snowball into bigger problems. These sounds often signal underlying issues like electrical malfunctions, loose components, or motors on the verge of failure. If left unattended, these problems can escalate, leading to expensive repairs, system breakdowns, or even higher energy bills.

Tackling the issue early can save you from unnecessary headaches and keep your HVAC system running smoothly. The certified technicians at Eco Temp HVAC are experts at diagnosing and fixing these problems. They provide dependable solutions designed to optimize efficiency and keep your system performing at its best.